With my traditional jewelry-making background, I’ve discovered that tools like a pulse arc welder are true game-changers for jewelry making. As someone who runs two businesses: Metalsmith Society and my own jewelry business, I’m constantly juggling tasks and looking for ways to be more efficient. This has driven me to seek out tools that save time without sacrificing quality. That’s how I discovered pulse arc welding. As an educator I also believe there is tremendous value in jewelers understanding how this technology works, even if they don't currently own a pulse arc welder. You may have a jewelry customer in need of a repair that requires a pulse arc welder or laser!

In this blog, I’ll share my journey with the pulse arc welder, including how it works, the creative possibilities it unlocks, and how it complements traditional techniques like soldering. We’ll dive into time-saving methods like tack welding, and discuss its role in the growing trend of permanent jewelry. I even go over the key differences between pulse arc welders and laser welders, helping you choose the right tool for your needs. Whether you’re a beginner or a seasoned jeweler, this guide will show you why the pulse arc welder deserves a place in your toolkit.

My First Experience With A Pulse Arc Welder

At a conference a few years ago, I witnessed a live demo of a Sunstone Orion mPulse™ and was immediately captivated. During the demo they were fusing forever bracelets, re-tipping a prong and fixing porosity on a casting. I got to give it a try at the conference and found it was easy to start using. It really got me curious about how I could use one with my own jewelry business and I decided to invest in one.

How I Used It For Jewelry Making

The pulse arc welder quickly became an essential part of my process for repairing and attaching delicate chains, closing thin jump rings, and securing findings with precision and ease. Its advanced technology enables quick, clean welds that minimize heat exposure, ensuring even the most fragile components remain intact and undamaged. For soldering situations where I feared melting a chain or accidentally fusing links together, the welder provided a safer, more controlled alternative. An added bonus? I could attach a clasp to a chain without worrying about oxidation or altering the temper of the metal. Unlike a traditional torch, whichheats metal and returns it to a dead-soft state, the pulse arc welder keeps the metal’s properties stable, making it ideal for working with delicate components.

The Time-Saving Magic of Tack Welding

In this image this gold ring shank has been positioned and tack welded to the bezel.

In this image this gold ring shank has been positioned and tack welded to the bezel.As I gained more confidence with my pulse arc welder, I started experimenting with tack welding, and let me tell you—it has become the biggest time-saver in my process! Tack welding involves using a few quick welds to connect components that will eventually be soldered. It secures my pieces just enough so that I can solder them quickly without anything shifting. This technique simplifies tasks like centering a bail on a pendant, setting up complex or uneven pieces, and even attaching prongs. Now, while the pulse arc welder is fabulous, I should mention that in many instances it doesn't replace my need for soldering; rather, it complements it, making my workflow smoother and more efficient. In the case of the gold ring in the above image, I first ensured my ring shank was perfectly centered and at the correct height then tacked it. I cleaned it up and then I soldered as normal with medium solder. Tacking allowed me to simply put the ring on a block to solder with no danger of anything becoming askew, isn't that the worst! You can see that after the solder has flowed there is no evidence the welder was ever used!

A 14k yellow gold ring after it has been soldered.

A 14k yellow gold ring after it has been soldered.Creative Possibilities Unleashed

The pulse arc welder has truly expanded my creative horizons; I have experimented with connecting chains directly onto bezel settings, even with fragile stones already set. You still want to keep your weld away from the stone, but you can get pretty darn close. I've also been able to ball the ends of wire effortlessly using the welder, which opens up a whole new world of design possibilities for cold connections! The welder gives me the flexibility to experiment and push the boundaries of my designs. It’s amazing how this tool has not only streamlined my workflow but also ignited my creativity!

Welding Filler Wire into Your Work

Most of what I have discussed has been utilizing smaller welds, but sometimes a filler material is required when using a pulse arc welder. The type of filler wire you use depends on the metal you’re working with. For precious metals like gold, you’ll want to match the filler wire to the karat and color of the base metal, whether it’s 14k yellow gold or 18k white gold. For silver, fine silver or sterling silver filler wires work best, while platinum projects require platinum filler wire for a strong, seamless finish. If you’re working with base metals like copper, stainless steel, or titanium, you’ll need corresponding filler wires to match their composition. The key is to choose a filler wire that’s thin enough to fit the weld area (typically 0.5mm to 1mm for jewelry) and to prep it by cleaning off any oxidation. While you don’t always need filler wire—like when closing jump rings—it’s essential for filling gaps or reinforcing larger welds. It’s just another way the pulse arc welder keeps things versatile and efficient! To get started you use, I position the electrode at about a 45-degree angle near the contact point between the wire and the base material. Then, I initiate the welding process, making sure the base material melts first. This allows the surface tension to draw the wire into the weld pool. For larger wires, I’ve learned that I may need to crank up the energy settings a bit to ensure they melt thoroughly. Key points to keep in mind are proper electrode placement, wire prep (sometimes I ball the end of the wire to provide more material for the weld), and adjusting energy based on wire size. This technique has opened up new possibilities in my designs, and I’m excited to keep experimenting!

Embracing the Learning Curve

Practicing and experimenting with your pulse arc welder is crucial, especially since there’s definitely a learning curve involved! I’ve learned firsthand that applying too much power can lead to unwanted concave areas in your work, which is not what we want as jewelers. Just like with soldering, it’s essential to ensure that the two areas you're connecting are perfectly flush to achieve a strong, seamless weld. Taking the time to get comfortable with your settings and techniques will pay off in the long run, helping you create cleaner, more precise connections and allowing your creativity to flourish. So don’t rush the process—embrace the learning journey and enjoy discovering the full potential of your welder!

Connecting with the Community - Permanent Jewelry Events

It has also opened up new business opportunities, particularly with the trend of permanent jewelry. According to Glimpse, a internet trend-spotting platform, over the past year, interest in permanent jewelry has risen by 17%, with approximately 262,000 monthly searches as of November 2024.

Last year, I hosted my first permanent jewelry event, collaborating with a local luxury eyewear store. Customers had the chance to have bracelets, anklets, or necklaces fused onto them using the welder—creating unique, permanent pieces that symbolize special moments like friendships or anniversaries.

What struck me most was how this experience brought me out into the community. Customers watched me work, and many were just as amazed as I was during my first encounter with the welder. I also had a bunch of my jewelry pieces in a case for people to check out and shop while they waited for their appointment. The event not only provided a great way to connect with people but also proved to be highly profitable. Permanent jewelry is a lucrative service, with significant margins on 14k gold chain bracelets, for instance. As I continue to explore the world of permanent jewelry, I’m thinking about how to set myself apart by incorporating custom charms, unique castings, or mixing metals. I have also had customers who wanted a clasp, but you can still give them an awesome experience and customize different charms and chains on the spot.

You can also connect with your fellow jewelers at Sunstone's annual Permanent Jewelry Expo Event. I have attended and it was awesome they have guest speakers lecture on branding, money and more. Venders that sell all types of wholesale chain and findings and you make a ton of friends! This year it is May 15-18, 2025 in San Antonio. More info at www.pjexpo.org

How does the welder work?

My Sunstone Orion mPulse® is super user-friendly and versatile, making it a breeze to tackle all kinds of projects. Start by setting up your welder. Ensure your piece is properly grounded using the grounding clip to complete the circuit. Then, adjust the energy settings, position the stylus at the weld joint, and activate it to create a clean, strong weld.

Just remember, don’t press too hard—doing so can make the electrode stick or wear out quickly. If you’re looking to speed things up, the welder has an argon gas accelerator that kicks in when you’re doing multiple welds, which is a game changer. You can also play around with preset weld settings to find what works best for you, but it’s a good idea to start with lower energy levels and ramp up from there. And don’t forget about maintenance! Keeping your electrodes sharp with a diamond wheel will help you get smooth, stable welds.

FAQ

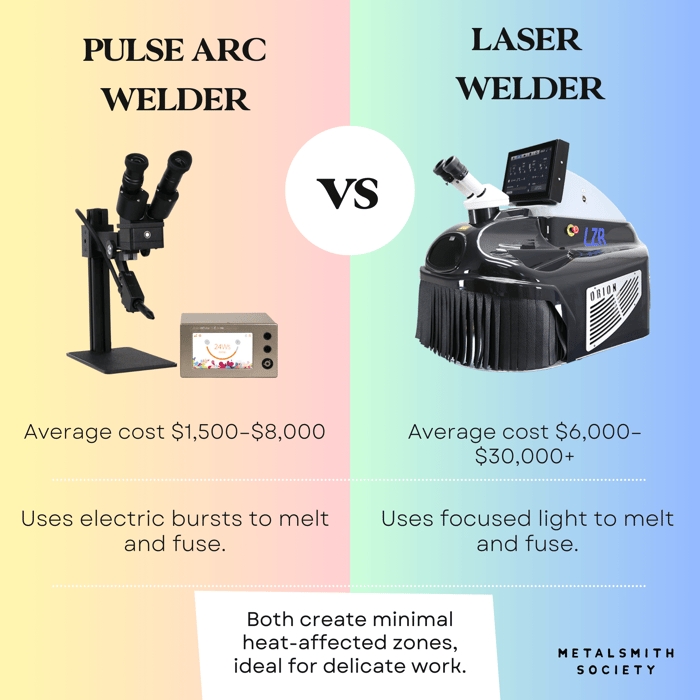

What is the difference between a Pulse Arc Welder and a Laser Welder?

Great question! A laser welder uses a concentrated laser beam to create ultra-precise and clean welds, making it perfect for delicate jewelry repairs and assembly, especially near gemstones, but it comes with a higher price tag. A pulse arc welder, on the other hand, uses controlled bursts of electricity to produce strong, reliable welds, offering versatility and precision for a variety of metals at a more budget-friendly cost.

Can I replace soldering with my welder?

It depends on the type of welder you’re using!

If you’ve got a laser welder, the answer is a definite “Yes!” A laser welder skips the whole soldering process by directly fusing metal edges at the joint. Its ultra-concentrated beam creates intense, localized heat, seamlessly melting the metal together without needing solder or flux. This makes the process super clean, fast, and efficient—perfect for delicate work while keeping the surrounding areas pristine.

Now, if you’re working with a pulse arc welder, the answer is a little more nuanced. A pulse arc welder provides precise, controlled heat, making it fantastic for assembling and repairing jewelry without a full soldering setup. However, it doesn’t directly fuse the metal edges like a laser does. Instead, it melts a small area with an electric arc, often requiring filler material (like wire or solder) to complete the bond. For example jump rings and chain would require no filler but connecting larger areas would require filler wire. While it’s a versatile and cost-effective tool, it doesn’t quite match the pinpoint precision or direct fusion capabilities of a laser welder.

So, while both tools can step in for soldering, a laser welder fully replaces it, whereas a pulse arc welder offers a strong alternative with its own set of perks!

What metals can I weld with a pulse arc welder?

It works well with most metals, including gold, silver, platinum, palladium, and even titanium and stainless steel. As an added note, pulse arc welders are particularly effective on highly conductive metals like silver and copper, achieving deeper penetration. Laser welders may struggle with these metals due to reflection issues, making pulse arc welders a preferred choice for such materials.

What’s the learning curve like?

It’s relatively easy to get the hang of, especially with a little practice, making it a great tool for both beginners and experienced jewelers. You can check out a bunch of educational videos on resources on YouTube.

Which Pulse Arc Welder Should I Get?

The right pulse arc welder for you depends on your needs, budget, and the type of jewelry work you do. Here's a breakdown to help you decide:

For Beginners or Small-Scale Projects

Recommended Model: Orion mPulse®

Why?: This entry-level model is user-friendly and perfect for simple repairs, small jewelry pieces, or delicate work like attaching findings. They’re compact, affordable, and great for learning the ropes.

For Versatility and Mid-Level Work

Recommended Model: Orion 100c Pulse Arc Welder

Why?: It offers more power and features than the mPulse series, making it ideal for jewelers who need to tackle a wider variety of projects, including larger welds or working with thicker metals.

For Advanced or Professional Use

Recommended Model: Orion 200i or 250s

Why?: These models deliver high power and precision, perfect for complex projects or those requiring seamless welds on thicker or harder-to-work metals like platinum or titanium. They also handle production-level work efficiently.

For Permanent Jewelry

Recommended Model: Zapp Plus™

Why?: Specifically this affordable option is designed for creating permanent jewelry like bracelets and anklets, these welders are tailored for repetitive, quick welds and are perfect for on-the-go setups or events. You can also use them for jewelry making applications like tack welds, chain repairs and attaching findings.

What to Consider When Choosing:

Budget: Entry-level models are more affordable, while professional-grade welders come with higher upfront costs.

Project Scope: Match the power and features to the type of work you do (repairs, fabrication, permanent jewelry, etc.).

Portability: If you need to travel with your welder, choose a compact and lightweight model like the Orion mPulse.

Future Needs: If you plan to scale up your business, investing in a more versatile model like the Orion 150s or 200i might save you from upgrading later.

My community members can save 3% on their purchase (that’s $150 off a starter kit) when you use my code: CORKIE3. You can also save on accessories, chains and findings!SHOP WELDERS

While the pulse arc welder hasn’t replaced traditional jewelry making techniques, it has significantly enhanced my workflow. Tasks like soldering jump rings or connecting chains are now quicker and cleaner, allowing me to focus more on the creative aspects of my work. I’m excited to continue experimenting with my pulse arc welder and discovering new ways it can push the boundaries of my craft.

Follow me on Instagram @corkieboltonjewelry and visit my website at corkieboltonjewelry.com for more insights into my jewelry-making journey!

Disclosure: This post contains my affiliate links for Sunstone Welders, and your purchase through my link helps support my mission to share jewelry-making educational content across my blog, podcast, and Instagram community. I was also gifted a welder for my review, but all opinions shared here are entirely honest and based on my personal experience.